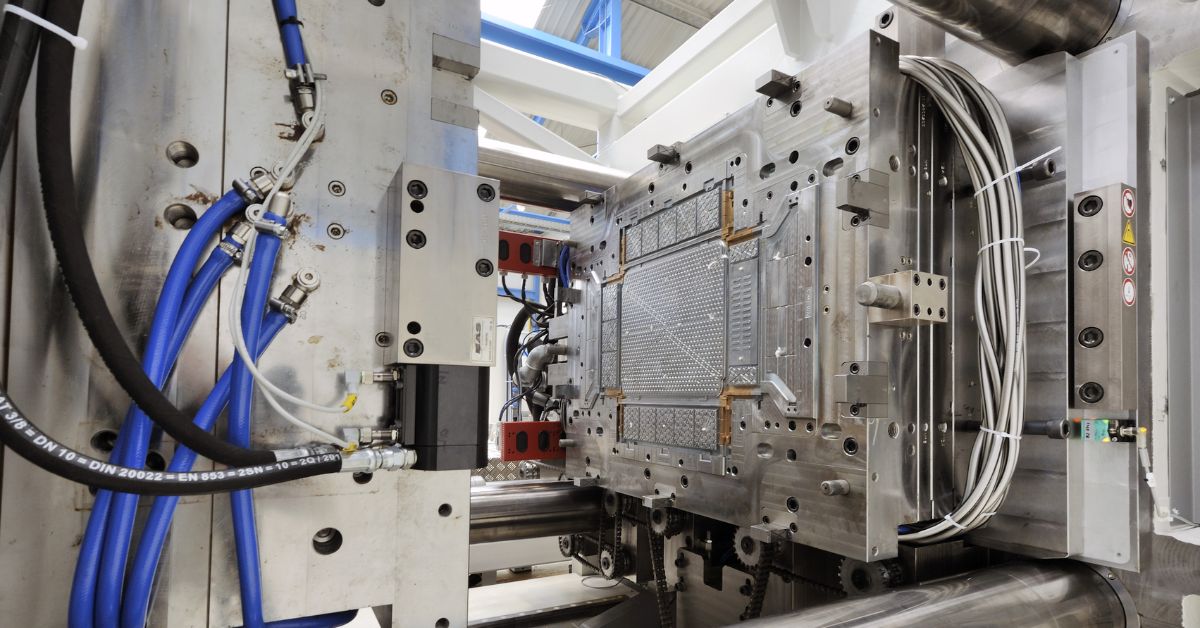

Plastic Injection Molding is one of the most importantly used production techniques for producing plastic elements. It’s a quite green and price-effective method, particularly for immoderate-volume production. From car additives to medical devices and regular patron merchandise, Ptms-Mold performs an important function in shaping the cutting-edge-day worldwide.

What Is Plastic Injection Molding?

Plastic Injection Molding China consists of melting plastic pellets (referred to as resin) and injecting the molten plastic proper right into a mildew hole area. The mould is normally made from steel or aluminum and is precision-engineered to form the shape of the very last product. Once the plastic cools and solidifies, the mildew opens, and the detail is ejected.

This device lets producers create complex and pleasant plastic additives with excessive accuracy and consistency. It’s exceptional for mass production due to the fact that the same mould can be reused hundreds or possibly masses of lots of instances.

Key Steps in the Injection Molding Process

- Clamping: The halves of the mould are securely closed the usage of a clamping unit.

- Injection: Heated plastic is injected into the mold hole region below immoderate pressure.

- Cooling: The plastic inside the mold cools and solidifies into the famous form.

- Ejection: Once the element is without a doubt traditional and cooled, it’s miles ejected from the mould.

- Repeat: The cycle then repeats, often in a depend of seconds for every component.

Materials Used

A huge type of thermoplastics are applied in injection molding, counting on the software program’s dreams. Common substances embody:

- ABS (Acrylonitrile Butadiene Styrene): Tough and effect-resistant.

- Polypropylene (PP): Lightweight and bendy.

- Polyethylene (PE): Durable and evidence towards chemical materials.

- Nylon (PA): Strong and located on-resistant.

- Polystyrene (PS): Inexpensive and smooth to mold.

Additives like colorants, UV stabilizers, or flame retardants moreover may be blanketed to alter the houses of the final product.

Advantages of Plastic Injection Molding

- High Efficiency: Once the mold is made, manufacturing cycles are very speedy.

- Consistency: Parts are same from one batch to the subsequent, ensuring uniform extremely good.

- Design Flexibility: Allows for complex shapes and complicated geometries.

- Low Waste: Excess plastic can often be recycled and reused.

- Cost-Effective for Large Volumes: The more components produced, the lower the rate consistent with the unit.

Common Applications

Plastic injection molding is used in some unspecified time in the future of almost every organization, along facet:

- Automotive: Dashboards, bumpers, clips, and covers.

- Medical: Syringes, casings, surgical devices.

- Consumer Goods: Toys, containers, cell telephone instances.

- Electronics: Connectors, housings, switches.

Considerations and Challenges

While injection molding offers many blessings, it moreover requires careful making plans:

- High Upfront Costs: Mold format and tooling may be pricey.

- Design Limitations: Some complicated elements also can need more than one mold.

- Lead Time: Initial setup and mold creation can take numerous weeks.

However, with proper making plans and the right information, those demanding conditions can be outcomes controlled.

Conclusion

Plastic Injection Molding in China is an effective production approach that combines pace, precision, and repeatability. Whether you’re generating small medical additives or huge car factors, it gives the terrific solution for excessive-amount, terrific plastic aspect production. As substances and eras keep on enhancing, the possibilities with injection molding are excellent growing.